Your Partner for Saint-Gobain Performance Plastics Products…

Since 15 years we distribute SGPPL Products and manufacture belts made out of genuine SGPPL Material

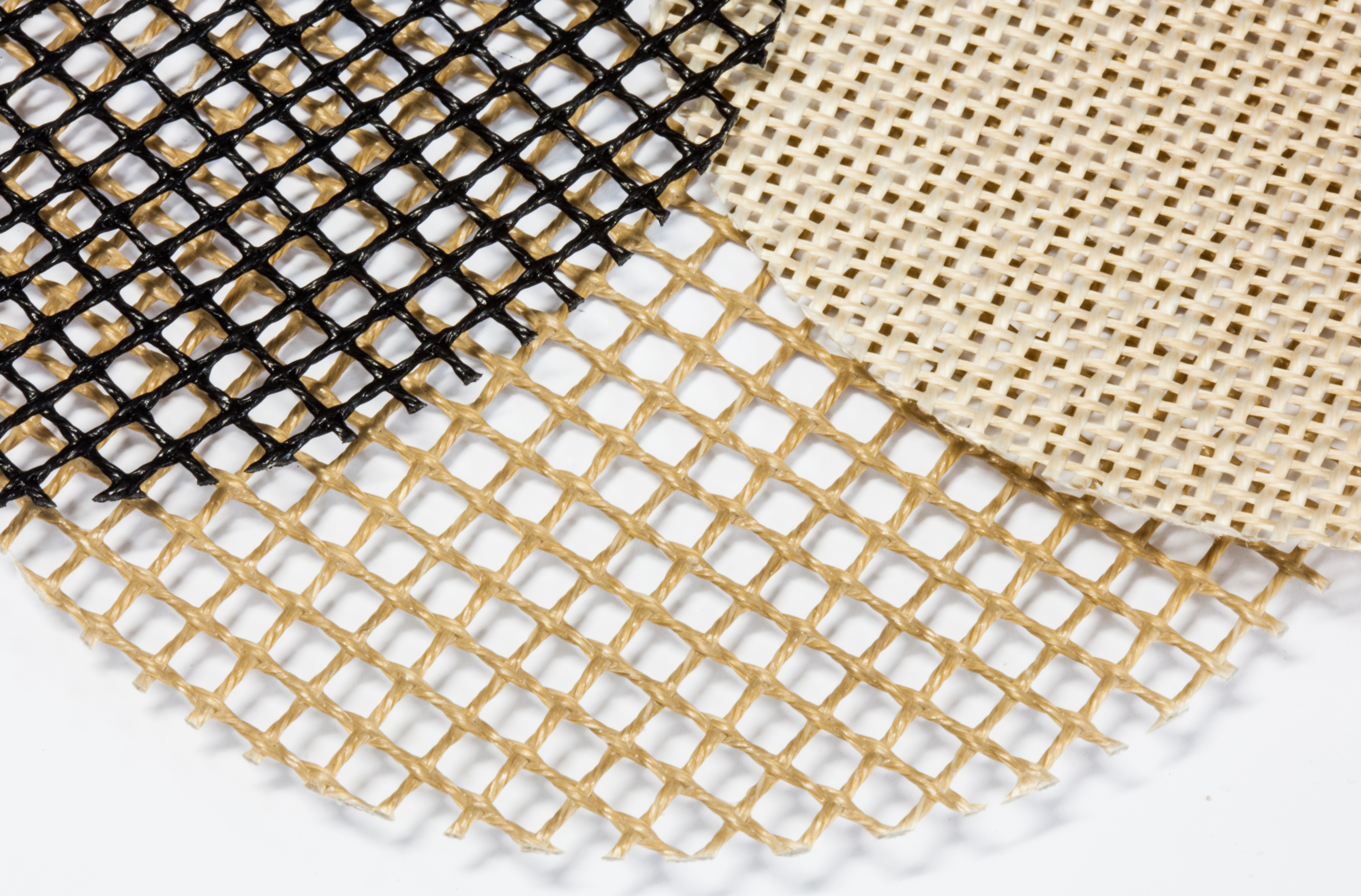

CHEMFAB® NON-STICK SOLUTIONS are the result of pioneering work to develop

high-temperature, chemically-resistant, flexible advanced materials. We support

our customers with in-house technical capabilities that are unmatched in the

industry. Our research staff conduct extensive studies in composites and

reinforcements, cast films, coatings, laminates and fabrication techniques. Pilot

plant and scale-up facilities are available to prototype your material.

CHEMFAB® NON-STICK SOLUTIONS Produkte entstanden ursprünglich aus der Idee,

temperaturstabile, chemisch widerstandsfähige und flexible Materialien zu entwickeln.

Durch unseren hohen technischen Standard und unser Know-how unterstützen wir

unsere Kunde Ihre Ziele schnell und effizient zu erreichen. Unsere Entwicklungs ab teil –

ungen arbeiten kontinuierlich an Optimierungen von Verbundwerkstoffen, Geweben,

Beschichtungen, Laminaten, PTFE Giessfolien und Fabrikationstechniken.

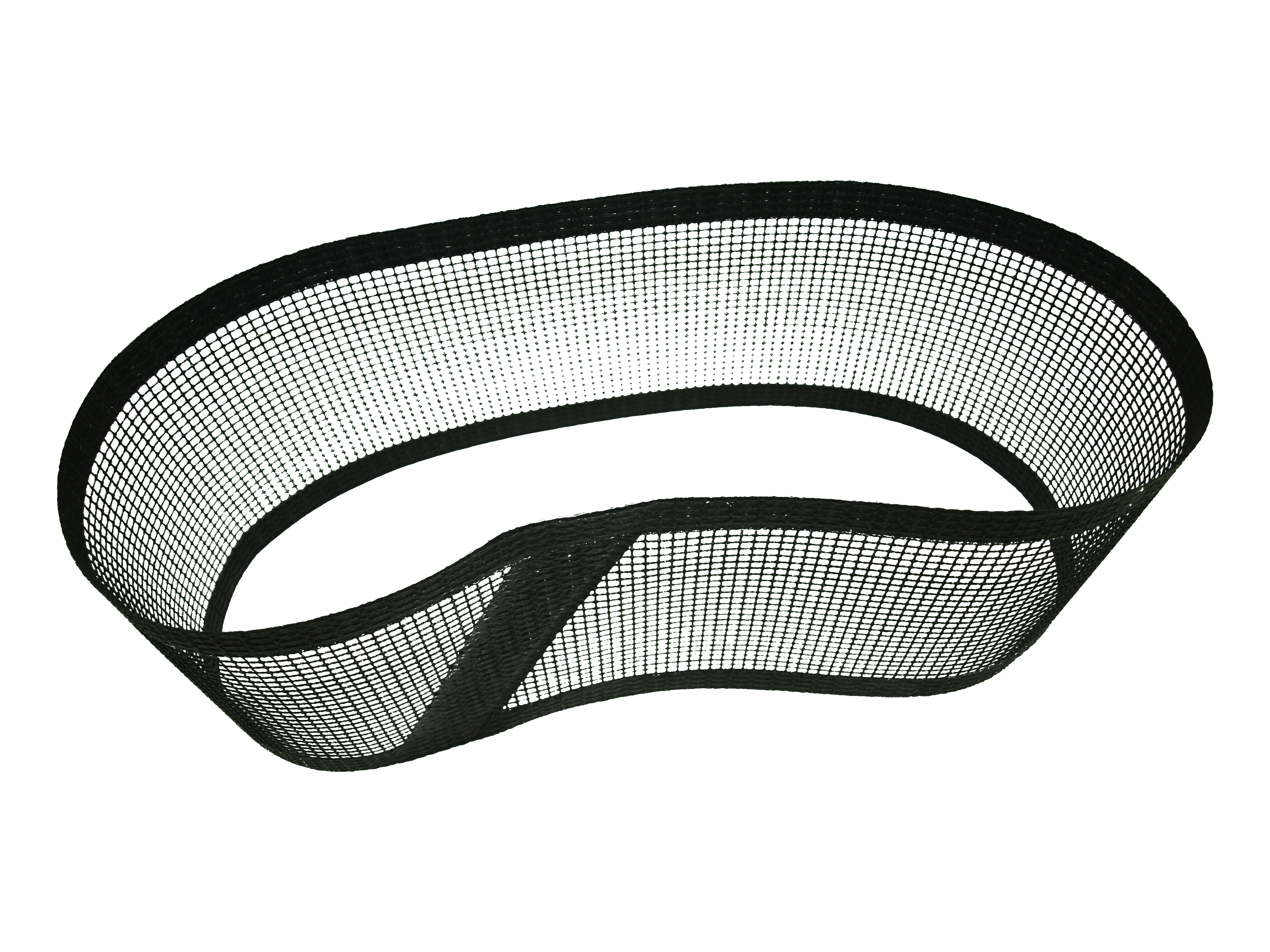

…Belting and more